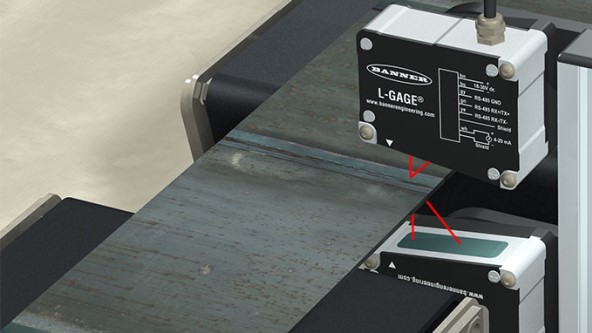

Sheet Metal Thickness Measurement

In the automotive industry, sheet metal stamping is the process of cutting and shaping metal alloys into automotive frame brackets and other forms using a press tool.

Metal stamping dies are used to create high precision metal parts that are equal in shape and size.

Automotive metal stamping requires a specific thickness to ensure the parts are equal, andthe die is not damaged during this process. As metal sheets move down the conveyor, laser displacement sensors measure the sheets on a very precise scale to obtain the correct thickness. In this sheet metal stamping application, it is critical that the frame brackets and other metal components are identical and that the die is not damaged to prevent down time and costly repairs. Banner Engineering's LH laser displacement sensor is a perfect solution because it is highly accurate and measures thickness at micron levels.

YOUR BENEFITS

- Protects costly stamping dies from damage.

- Highly accurate thickness measurement at micron levels, even with dark and discoloured material.

- 4-20mA analogue or RS-485 communication outputs.

The L-GAGE LH Series can also consistently look at dark targets on these levels. The LH’s 1024 pixel CMOS linear imager is capable of micrometer-level resolutions ranging from 1-10 microns, which gives it the ability to measure thickness of sheet metal quickly and accurately. Thickness measurements are available with 4-20 mA analog or RS-485 digital communication outputs.

The LH sensor pair self-synchronize to take measurements and calculate thickness within the sensors. The system doesn't require an external controller and is easily configurable using Banner's graphical user interface or GUI, which allows simple networking and monitoring for system-wide visibility of process measurement.

For this specific thickness measurement application, the "master/slave separation," which is two times the reference plus nominal distance, is the ideal separation between the two sensors.

- Automobile

- Press Shop – Tool Identification

- Sheet Metal Thickness Measurement

- Body Shop – Welding Nut Detection

- Paint Shop – Skid Identification

- Area Guarding for Robotic Cells

- Final Assembly – Robot Assembly

- Inspection of Tips on a Welder

- Final Assembly – Diagnosis of Leaks

- Tier 1 – Bumper Identification

- Manual Feeding in Weld Cell

- Powertrain – Contactless Verification

- Body Detection in Automobile Production

- Detecting Black Parts on Black Door Panel

- Moonroof Clear Glass Detection

- Long-Range Inspection in Automotive Assembly

- Rubber Washer Detection on Engine Block

- Engine Block Part-In-Place Detection

- Electric Vehicle Detection in Charging Station

- Vehicle Detection in a Self-Serve Car Wash

- SUCCESS STORIES

- RFID Guides AGV in Suspension Production

- IO-Link Wired Silencer Production

- Workpiece Carrier Identification in Rear Vent Production

- Weld Nut Sensing

- RFID Traceability

- RFID in Engine Production

- Bumper Production with Identification

- Solutions for Paint Shops

- Welding and Assembly Sensors

- Angle Sensors for Assembly Systems

- Tool Identification

- RFID Identification of Injector Nozzles

- RFID in the Body Shop

- IO-Link Eases Differential Gear Production

- Pick-to-Light for Bumper Assembly

- RFID and I/O Modules for Safe Tool Changes

- Ply Orientation Inspection

- Chimie

- Detection of Pigs

- Remote Signal I/O

- Easy Connection of Field Devices

- Remote Tank Level Monitoring with DX70

- Signal Processing with System I/O in the Control Cabinet

- Signal Separation with Interface Technology in the Control Cabinet

- Identification of Hose Connections

- Efficient Monitoring of Cabinets in the Field

- Monitoring of Quarter Turn Actuators

- Planning and Assembly of System Solutions

- Success Stories

- I/O System Excom Creates Space in the I&C Rooms

- Zone 2 and 22 RFID

- Efficient Testing Control

- Intrinsically Safe Field Communication

- Process Control System Partnership

- Hazardous Area Remote I/O

- Dual Valve Position Feedback

- Flexibility with Fieldbus

- Asset Management with Remote I/O

- Correct Positioning with RFID in Carbide Production

- Energie

- Agro-alimentaire

- Dough Height Inspection for Accurate Measurement

- Dough Thickness Control in Rolling Machines

- Leading Edge Detection of Plastic Container

- Identification of Food Containers

- Date/Lot Code Verification

- Container Check

- Detection of Valve Position

- Barcode Reading on Depalletizer Station

- Reliable Cap Orientation Verification in Aseptic Areas

- Detection of Pipe Elbows

- Clear and Tipped Bottle Detection on Depalletizer

- Clear Plastic Bottle Detection

- Identification of Chocolate Moulds

- Frozen Food Packaging Label Inspection

- In-Line Bottle Accumulation on Single Filer

- Detecting Refrigerated Breakfast Rolls on a Multi-Lane Conveyor

- Success Stories

- Track and Trace in Meat Production with RFID

- Contact-free Encoder in Potato Production

- UHF RFID in Food Distribution Center

- RFID for Chocolate production

- Distributed I/O for Food Equipment

- Remote I/O for Distilleries

- RFID and Autoclaves

- IP67 Power Supplies for Conveyors

- Transparency in Chocolate Manufacturing

- Identification in Food Product Storage

- Equipement Mobile

- Distribution Lines for Field Sprayers

- Loading Dock Occupancy Monitoring

- Measuring the Ground Clearance on a Field Sprayer

- Monitoring Railcars Wheels Wirelessly

- Reach Stacker Status With Bright Lighting Indicators

- Angle Measurement on a Field Sprayer

- Determining the Boom Angle Position

- Material Flow Monitoring on a Combine Harvester

- Vehicle at Loading Dock

- Equipment Compartment Illumination on Fire Engines

- Wireless Forklift Signaling

- Two-Axis Tilt Measurement on a Combine Harvester

- Success Stories

- Position Measurement with RFID and Encoder

- Speed Control via Radar Sensor QT50

- RFID Guides AGV in Suspension Production

- Block I/O Modules on Super Yacht

- Wear-free Encoder on Hopper Dredger

- I/O for Dust Suppression

- Cabinet Cooling

- Quick Disconnect Connectivity

- Automation Solutions for Extreme Cold

- Remote I/O for Cranes

- Rugged Heavy Metal Lifting

- Rollercoaster Positioning

- Mobile Machinery Solutions

- Exact Height Positioning

- Critical Angle Sensing

- Angle Sensor Detects Platform Lift

- Predictive Maintenance of Machine Parts at Port-Based Coal Conveying Facility

- Pétrole et Gaz

- Emballage

- Identification of Printing Color Cartridges

- Reliable Operation of Machines

- Monitoring of Caps in Filling Lines

- Monitoring Changeover Processes

- Identification of Test Bottles

- Level Monitoring of Ground Coffee

- Box Insert Detection

- Carton Dimensioning

- Clear Container Detection

- Correct Label Verification

- Detecting Different Size Packages on a Conveyor

- High-Speed 2D Barcode Inspection

- Multicolored Reflective Package Detection

- Plastic Roll Diameter Measurement

- Tube Positioning Using a Registration Mark

- Vertical Form Fill Seal Machine Solutions

- Success Stories

- Pharma

- Monitoring of Quarter Turn Actuators

- Detection of Pipe Elbows

- High-Speed Tablet Counting With Fiber Amplifier

- Remote Signal I/O

- Planning and Construction of Super Skids

- I.V. Bag Liquid Detection

- Easy Connection of Field Devices

- Identification of Portable Tanks

- Identification of Cryovessels

- Identification of Mobile Containers

- Liquid Level Monitoring In A Large Tank

- Identification of Mobile Containers with Handheld Devices

- Identification of Hose Connections for Precursors

- Identification of Hose Connections in Sterile Areas

- Identification of Hose Connections in Ex Zone 1

- Identification of Big Bags and Bioreactors

- Identification of Single-Use Applications

- Semi-conducteur